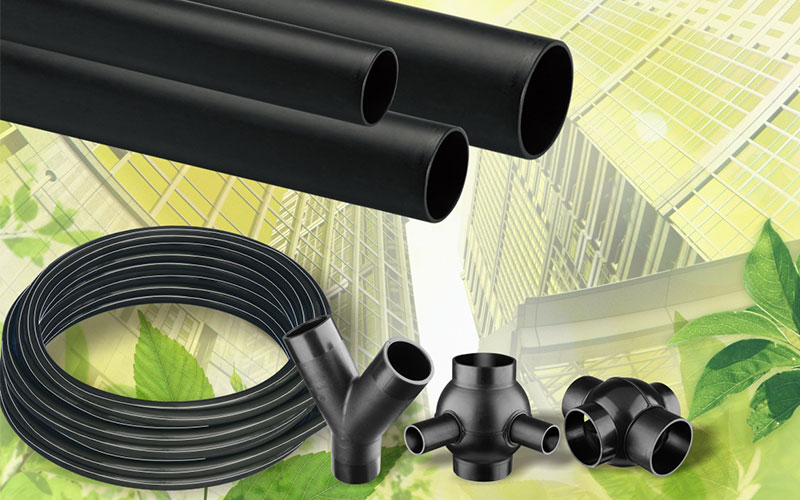

Exploring American Plastics HDPE Pipe Manufacturing and Its Role in Modern Infrastructure

Wiki Article

Comprehending the Trick Conveniences of HDPE Pipe for Water and Wastewater Administration

Making use of HDPE pipeline in water and wastewater management provides various benefits that merit consideration. Its outstanding sturdiness and long life-span make it a favored choice for numerous tasks. Furthermore, the material's resistance to corrosion and chemical damages improves its dependability in different environments. The benefits expand past simply long life and resistance. Pipe Supplier American Plastics Midland. Discovering its cost-effectiveness and ecological influence exposes much more compelling factors for its prevalent fostering in contemporary infrastructurePhenomenal Sturdiness and Long Life

HDPE pipeline sticks out for its exceptional resilience and durability, making it a recommended option in water administration systems. Constructed from high-density polyethylene, these pipelines can withstand considerable stress and stress and anxiety, making sure reliable performance gradually. Their durable nature permits them to withstand extreme ecological conditions, including temperature fluctuations and soil activities, which can cause other materials to fall short.

The lifespan of HDPE pipelines typically exceeds half a century, supplying an economical service for districts and markets alike. In addition, the material's lightweight properties streamline installation, lowering labor prices and durations. This sturdiness decreases the demand for regular repairs or substitutes, even more enhancing its financial charm.

In water management applications, the integrity of HDPE pipes means less disruptions and enhanced solution continuity, making them integral to lasting framework advancement. The combination of durability and long life strengthens HDPE's function as a cornerstone in reliable water management options.

Resistance to Rust and Chemical Damages

While several materials yield to deterioration and chemical damages in time, HDPE pipelines show remarkable resistance, making them optimal for numerous water administration applications. This resilience originates from the molecular structure of high-density polyethylene, which is naturally non-reactive and does not wear away like steels or break down from exposure to harsh chemicals. As an outcome, HDPE is extremely reliable in environments with aggressive substances, such as wastewater systems that may contain acids, bases, and natural solvents.

Furthermore, HDPE pipes can endure ecological factors such as dirt level of acidity and saline conditions, better enhancing their suitability for varied applications (Texas hdpe pipe manufacturer). Their capability to keep structural stability with time lowers the risk of leaks and failures, which is essential in guaranteeing the safety and security and dependability of water circulation and wastewater administration systems. Consequently, the resistance to deterioration and chemical damage substantially adds to the total performance and durability of HDPE piping remedies

Cost-Effectiveness and Financial Benefits

When considering the economic effects of water administration systems, the cost-effectiveness of HDPE pipes becomes noticeable. These pipelines supply reduced installation and upkeep costs contrasted to traditional products like metal or concrete. Their light-weight nature simplifies transport and installment, leading to reduced labor expenses. Furthermore, HDPE pipelines display a long life-span, commonly exceeding 50 years, which converts to fewer substitutes and long-lasting savings.The resistance of HDPE to deterioration and chemical damage reduces the demand for expensive repair services and substitutes. The pipelines additionally support reliable water flow, decreasing energy prices connected with pumping systems. By alleviating leaks and water loss, HDPE pipelines add to considerable financial benefits for communities and industries alike. In general, the preliminary financial investment in HDPE piping can produce substantial monetary returns over the lifespan of the water monitoring system, making it a sensible choice for lasting infrastructure growth.

Ecological Sustainability and Reduced Impact

Convenience and Adaptability in Setup

Since of their distinct buildings, HDPE pipelines use amazing flexibility and flexibility in installment, making them appropriate for a wide variety of applications. elbow pipe Their lightweight nature enables much easier handling and transportation, lowering labor expenses and installation time. HDPE pipelines can be curved and formed to fit various surfaces and project demands, which is particularly beneficial in challenging atmospheres.Furthermore, their resistance to deterioration and chemical damage permits setup in diverse setups without the demand for specialized protective finishings. The capability to fuse joints creates a continual, leak-free system, enhancing the general integrity and reliability of the installment. HDPE's adaptability additionally suits ground activity, lowering the threat of damages in locations prone to shifting dirt. Generally, these characteristics make HDPE pipelines not just functional yet also a recommended option for water and wastewater management systems.

Regularly Asked Inquiries

Just How Does HDPE Pipe Contrast to PVC in Water Management Applications?

HDPE pipeline supplies exceptional adaptability, resistance to rust, and sturdiness contrasted to PVC. Its lighter weight assists in much easier installment, while its long lifespan minimizes substitute expenses, making HDPE a preferred selection in water administration applications.What Is the Life-span of HDPE Water Lines Under Regular Problems?

Under normal conditions, HDPE pipes can have a lifespan ranging from 50 to 100 years. Their longevity and resistance to corrosion add to their lasting efficiency in various applications, making them a trusted option for facilities.Are HDPE Pipeline Recyclable After Their Life Span?

Yes, HDPE pipes are recyclable after their life span. American Plastics HDPE Pipe for Oilfield. They can be processed and repurposed right into new products, considerably minimizing ecological effect and promoting sustainability within the sector, making them an eco-friendly option for piping servicesWhat Is the Installation Refine for HDPE Pipeline?

The installment process for HDPE pipes includes website preparation, trenching, pipe combination or mechanical signing up with, backfilling, and stress testing. Appropriate strategies guarantee a durable and reliable system for moving water and wastewater properly.Can HDPE Piping Be Used for Both Potable and Non-Potable Water Systems?

Yes, HDPE pipes can be made use of for both drinkable and non-potable water systems. Their versatility, resilience, and resistance to rust make them appropriate for numerous applications, making certain safe and efficient transportation of water in different contexts.Report this wiki page